|

PARTS LIST

(for

0 ~ 1.999 V) |

Resistors

(1 or 2%)

Important : if you have problem

reading the color code of precision resistors, please use a digital ohm

meter to check & confirm the value of each resistor before insertion

R

1 -- 3 K

R 2 -- 3 K

R 3 -- 39 Ω

R 4 -- 470 Ω

R 5 -- 100K

R 6 -- 470K

R 7 -- 1M

R 8 -- 10 Ω

*

R 9-- 10K *

R10 -- 470 Ω

Q1 --- 2.5V precision

Voltage reference IC (# TL431)

Datasheet

(pdf)

Diode

D1 -------- 1N4007

rectifier diode

D2 & D3 -- 1N4148 switching diodes

W1 --- Multi turn

precision trimmer pot

5K (# 502)

|

14-pin DIP IC

socket (for IC1)

40-pin DIP IC socket (for IC2)

PCB connectors -- 2-pin (2.54mm

pitch)

Capacitors

C1 -- (not

required)

C2 -- 100pF ceramic cap (# 101 or 100p)

C3 -- 0.1 uF mylar cap (# 100n or 104)

C4 -- 4.7uF E.cap

C5 -- 4.7uF E.cap

C6 -- 0.47uF (# 474 or 470n)

C7 -- 0.22uF (# 224 or 220n)

C8 -- 0.01 uF (# 103 or 10n)

C9 -- 0.1 uF ceramic cap (# 104 or 100n)

Double

side, FR4 printed circuit board

included

IC1 -- CMOS hex inverters (# 4069)

Datasheet (pdf)

IC2 --- 3

1/2

digit Panel Meter IC

(# ICL7107)

Datasheet

(pdf)

Disp 1 & 2 -- 2 pcs of double,

common anode 7-segment displays

|

|

CONSTRUCTION |

|

Please follow closely the

assembly procedure as stated below. The sequence of steps is very

important & should not be changed. The project is constructed on a

double-side

PCB .

Removing parts after

soldering is very difficult

!

Double-check the location & orientation of each component before

soldering. |

|

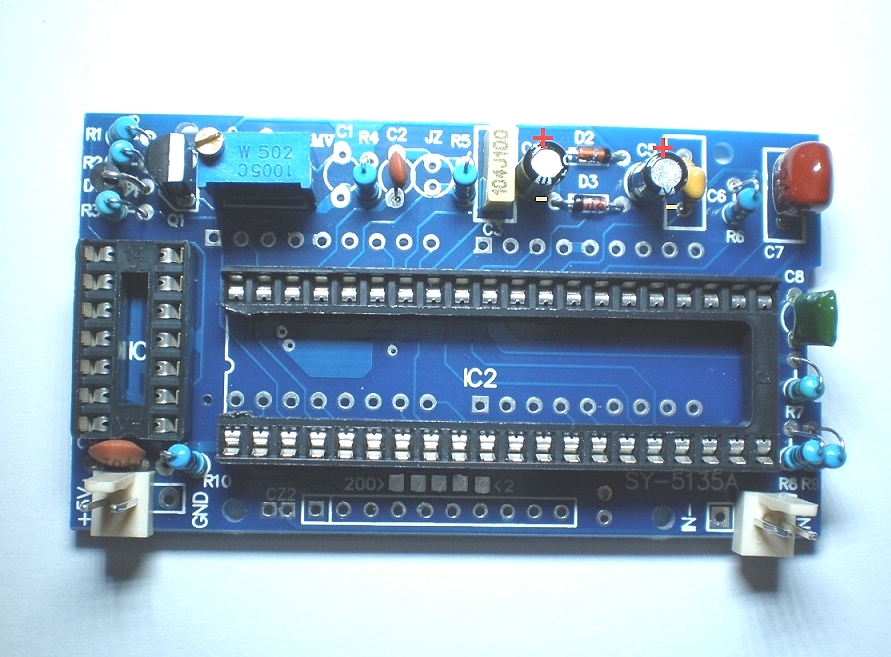

<STEP-1> insert & solder the

-> |

Resistors

Diodes

ceramic & mylar capacitors

electrolytic

capacitors

TL431 (Q1)

40-pin & 14-pin IC sockets

(empty sockets

without the ICs)

2-pin pcb connectors |

|

| Note : One end of the

40-pin IC socket has been intentionally cut to make soldering of the

displays (in step2) easier |

|

► |

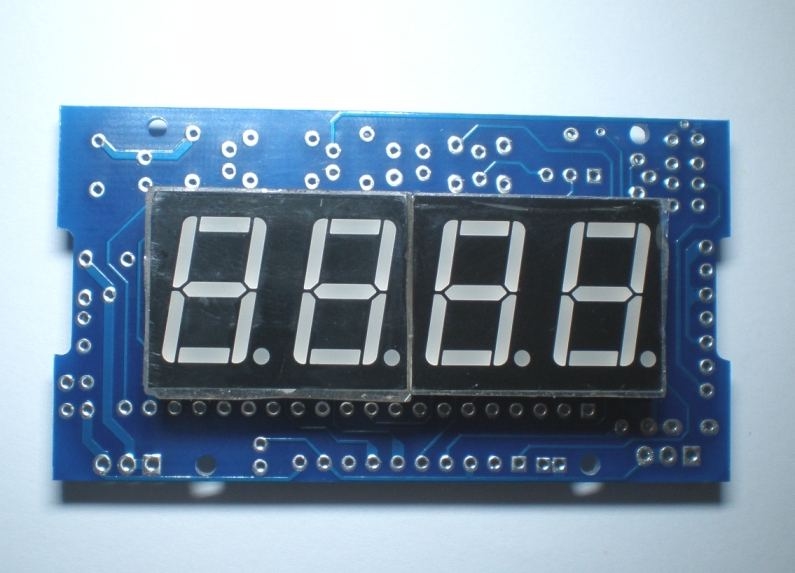

<STEP-2>

Insert & solder the 2-digit, 7-segment LED displays ( 2 pcs)

Watch for the orientation of the

displays

Please DO NOT insert the displays upside down !

|

|

|

|

▼ |

<STEP-4>

Test & Calibration

- Hook-up the test circuit (see diagram

below) & calibration the DPM as shown.

- You will need :

1) a stable 5V DC power supply to power up the DPM

2) an accurate digital voltmeter (2V F/s)

3) a 1.5V battery (any size) and

4) a small screw driver for adjusting the DPM's trim pot

Note that the actual voltage of the

battery is not important. It is merely used a temporary voltage

reference for calibration purpose. Our objective is to tune the DMP so

that it gives the same reading as the digital multimeter.

|

◄ |

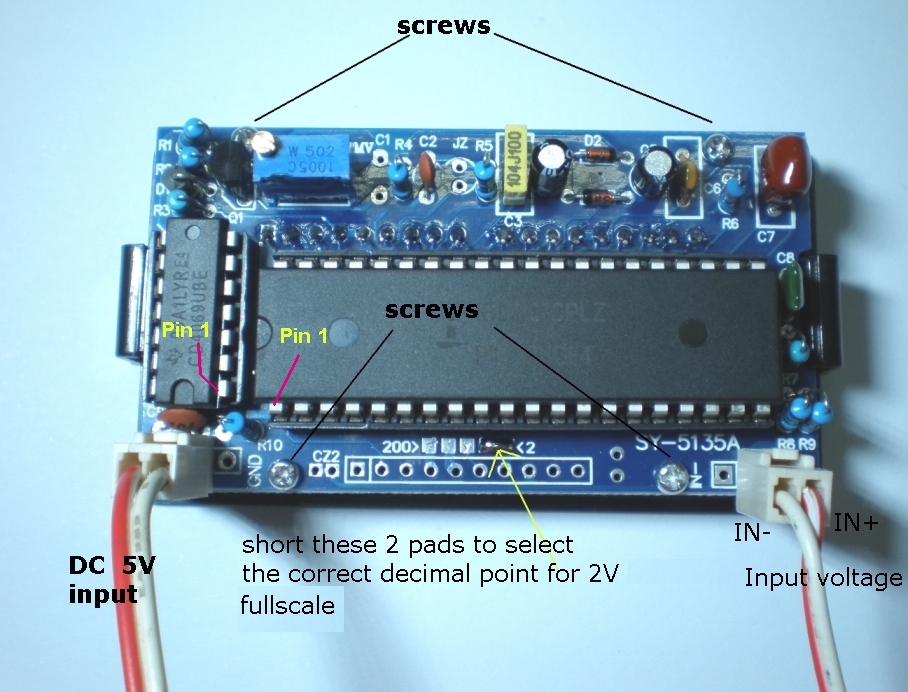

<STEP-3>

- Insert the ICs to their respective

sockets.

(ensure that the locations of pins # 1 are correctly

identified)

- Set the correct decimal point for

2V full-scale by shorting (with solder) the 2 rightmost pads (see

photo)

- Install the pcb on the plastic

snap-in panel mounting cover & secure it with 4 screws

- Insert the 2-pin wired connectors

(2 sets) to the pcb & proceed to the calibration step

|